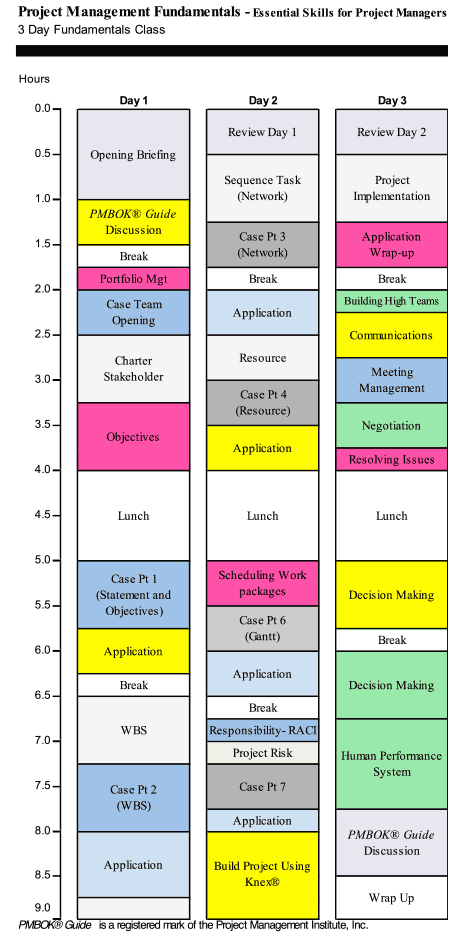

3 day Class

This class follows Project Management Institute’s steps for project excellence. (PMBOK 4th Edition)

Section 1:

- Definition of a project

- What is Project Portfolio Management

- Why you need to see the big picture

Section 2:

- Project Charter, find proper project direction

- Defining project stakeholders

- Your company project model (Stage gates, sign offs, capitol procurement, feasibility, other)

Section 3:

- Project objectives, measures and standards

- Getting approval before starting planning

- Developing a Work breakdown structure

- Understanding sub projects

- Developing work packages

Section 4:

- Sequencing task/work package order (network diagram – critical path)

- Planning resources needed (skills, materials, equipment, etc)

- Determine cost involved – get support

Section 5:

- Scheduling task/work packages (Gantt Chart)

- Scheduling all other resources

- Gaining commitment from stake holders

Section 6:

- Finding potential work package problems

- Developing a risk analysis – FMEA

- Look for additional opportunities

- Preparing for project execution

Section 7:

- Start to execute the project (Start up)

- Monitor project task outputs (Quality, time, etc)

- Modify project as issues arise

- Communicate changes

- Close the project

- Evaluate and document the project

Section 8

- How to manage Multiple projects

- Keeping stakeholders updated

- Handling project issues as they arise

Section 9

- People management

- Communication skills

- Meeting skills

- Involvement management

- Performance management

- Decision making

This is not a computer class, and no computer experience is necessary to complete the class. We do show some slides showing how certain steps look in MS Project so students can see how their project looks using software. We also give the worksheets to the students in an electronic form so participants can use their computer if they wish (MS Excel format).

Important Note – We ask that students bring a new or active project they are going implement to this class. Students will actually prepare a project during the class and they will return to work with a useable plan (or partial plan if large). We also send pre-work that a participant can use to prepare for the class if they wish.

Customized on-site training with multi-session discounts for companies with specific project needs.

Instruction:

Instruction:

This class is facilitated by Steven Reissig, who has many years of experience in both project managing and class facilitation.

In 17 years at Honda, Steve planned and executed numerous projects that had a huge impact at both Honda and its suppliers

Steve has taught Project Management at over 50 companies, and many have asked Steve to help integrate the process into their organizations. Steve is a member of The Project Management Institute, Inc., Society of Human Resource Management, and The American Society of Training and Development.

Some of the projects Steve has managed include:

- Facilitated the project leading Honda to win the Automotive Magazines Quick Die Change contest, setting a record for changing stamping dies in 3.28 minutes.

- Sub-managed a project that helped Honda to change from one model year to another in less than 90 minutes.

- Facilitated a team that eliminated air leaks on the stamping presses so well that one of six air compressors could remain shut down – saving half a million dollars per year!

- Developed a training program that allowed the stamping department to capture every process, including quality and operational procedures, to stop information loss.

- Started Honda University and self-directed work teams.

- Managed LEAN projects at Honda and suppliers.

- At a steel building manufacturer, led a project that dropped scrap from 11.7% to 9.9%, remakes from over 200 per month to less than 3, and brought on-time delivery from 27% to over 86% in just 3 months.

- At a mining company, helped project teams develop projects that were complete and came in on time and on cost.

- Facilitated a winter outage project at a gold mine in Alaska.

- Led a project that saved a food company over a million dollars per year in maintenance cost.

- Managed the building of over 50 houses AT ONE TIME for a high speed house manufacturer.

- Supervised various project teams in both manufacturing and office environments at Honda and other related companies.

Some other companies at which Steve has facilitated or instilled project management processes:

Honda of America, Hydro-One, CA., Bosch, Alpine Electronics, Johnson Controls, Nissan, TVA, Exon Mobile, NASA, Hinkle, BASF, Progress Energy, Encanna, Brunswick, Tellabs, Rio Tinto, Kennicott Mining, Buttler Mfg, Simplot, and many others.

-

Contact Us to get started!

-

Cick here to download a PDF of this page to share

-

Click here to download PMF 3-day class price sheet